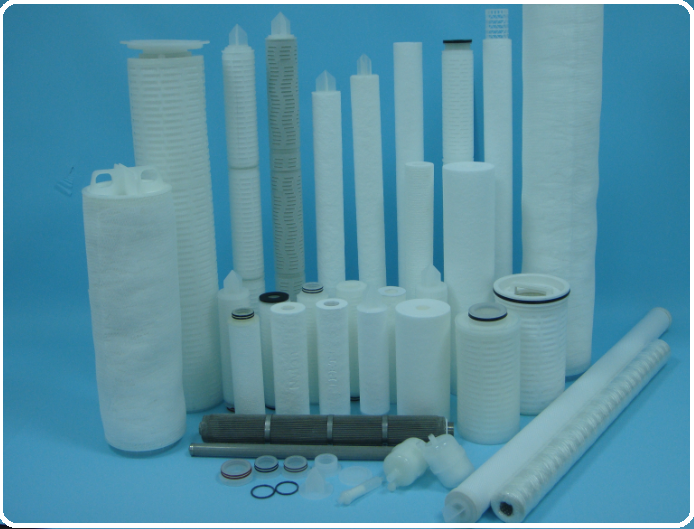

Nominal and Absolute

Bag Filters

Learn More

Oil Absorbing and High Efficiency

Bag Filters

Learn More

SW Series String Wound

Depth Cartridges

Learn More

Melt Blown NPP Series

For Industries

Learn More

Melt Blown APP Series

Depth Cartridges

Learn More

Melt Blown NPP & APP Series

Depth Cartridges

Learn More

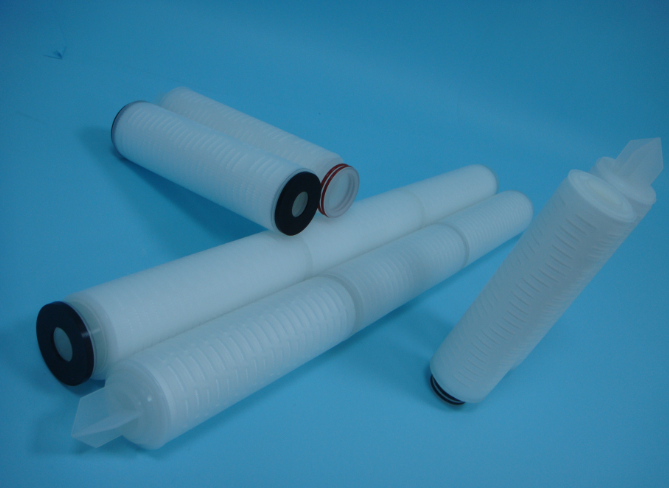

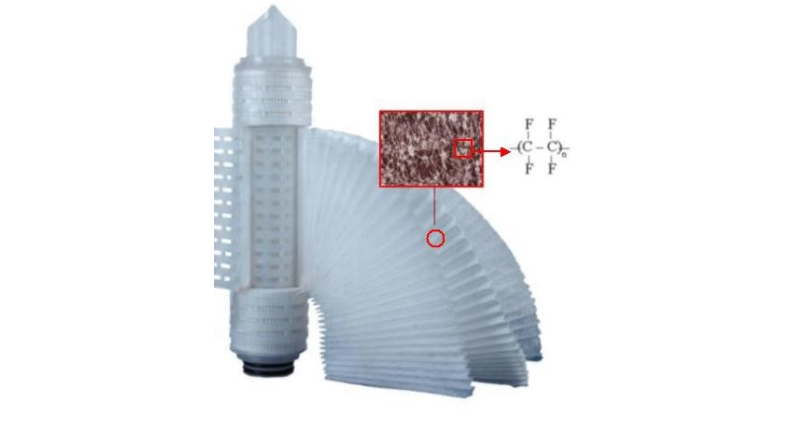

ExPleat PP Series, PSA and PSS

Pleated Filters

Learn More

ExPleat PP Series

Pleated Filters

Learn More

ExPleat PP Series, PSA Series

PSS Series and PFH Series

Learn More

PSA Series, PSS Series and PFH Series

Pleated Filters

Learn More

ExPleat PFH Series

PFH Series

Learn More

Deal in Electronics, Chemicals, Oil and Gas, Food & Beverage and Pharmateutical

Industries

Learn More

products for Plating

Industries

Read More

Injection Water Filtration

Chemicals, Oil and Gas

Learn More

Facilities Water

Pharmateutical

Read More